MIL-DTL-62267B(AT)

for at least 30 minutes, the engine should again be operated as above before

continuing break-in run. Proper oil pressure and temperature should be maintained

during operation on level ground, 60% grades, and 30% side slopes.

c. Operation and distance. Each chassis should be given a break-in run for the

distances specified in table VI on smooth, level, hard surfaced roads. The chassis

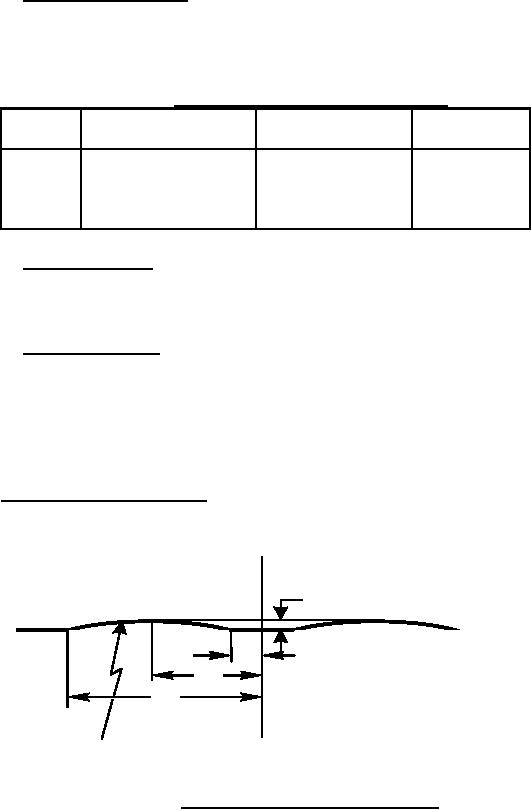

should be operated over the undulating section of road (see figure 1) during "a"

and "b" divisions of the break-in run, the undulating section will be bypassed.

TABLE VI. Speeds and distances for break-in run.

Division

of run

Speed mph (km/h)

Distance, mile (km)

Test conditions

a

0 to 10 (0 to 16)

10 (16)

Track (road)

b

11 to 15 (17 to 24)

15 (24)

Track (road)

c

16 to 20 (25 to 32)

10 (16)

Track (road)

d

21 to max. (33 to max.)

10 (16)

Track (road)

d. Reverse operation. After each division of the break-in run, the chassis should be

stopped, engine allowed to idle for not less than 2 minutes, and then driven in

reverse for a distance of not less than 50 ft (15 m) at speeds between 2 and 7 mph

(3 and 11 km/h).

e. Condition after run. After completion of the break-in run, the engine should idle

between 700 and 750 rpm. Prior to chassis being submitted to the Government for

acceptance, all suspension wheel bearings should be checked to determine if

adjustments are correct and readjusted as required. There should be no defects

indicative of damaged components or maladjustments that may cause faulty chassis

operation.

6.7 Changes from previous issue. Marginal notations are not used in this revision to

identify changes with respect to the previous issue due to the extent of the changes.

CENTER

L IN E

6"

3'

14'

25'

C O N T O U R A P P R O X IM A T E S

A 1 2 1 F T R A D IU S

FIGURE 1. Profile of test track (artificial bump).

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business