MIL-DTL-62013E(AT)

4.5 Method of inspection.

4.5.1 Materials. Conformance to 3.2 shall be determined by inspection of contractor

records providing proof or certification that materials conform to requirements. Applicable

records shall include drawings, specifications, design data, receiving inspection records,

processing and quality control standards, vendor catalogs and certifications, industry standards,

test reports, and rating data.

4.5.2 Defects. Conformance to 3.3, 3.3.3, 3.3.4, 3.3.6.2, 3.3.6.3, 3.3.7, 3.3.8.2, 3.3.8.3,

3.3.8.6, 3.3.9, 3.3.10, 3.5.5.1, 3.5.5.2, 3.5.5.3, 3.5.6, 3.5.16, 3.6, 3.7, 3.8, 3.10, 3.11, and 3.12

shall be determined by examination for the defects listed in table I. Examination shall be visual,

tactile, or by measurement with Standard Inspection Equipment.

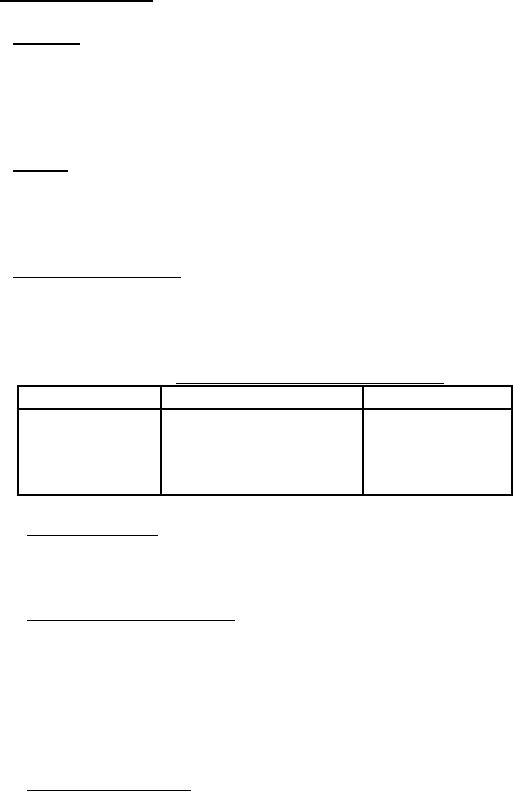

4.5.3 Break-in run procedure. To determine conformance to 3.4, each vehicle shall be

operated on smooth, level, hard-surfaced roads as specified in table III. The undulating portion of

the run shall be accomplished twice in each direction at speeds between 5 and 10 mph during

division "a" and between 11 and 14.5 mph during division "b".

TABLE III. Speeds and distances for break-in run.

Division of run

Speed - mph

Distance - miles

a

0 to 10

5

b

11 to 20

5

c

21 to 30

10

d

31 to maximum governed

10

4.5.3.1 Reverse operation. After each division of the break-in run, the vehicle shall be

stopped, the engine allowed to idle for not less than one minute, and the vehicle driven in reverse

for a distance of not less than 50 ft.

4.5.3.2 Oil pressure and temperature. Prior to the break-in run, the engine shall be

operated at 600 to 800 rpm until lubricating oil is at operating pressure and temperature. If at any

time during the break-in run the engine has been stopped for at least 15 minutes, the engine shall

again be operated, as above, before continuing break-in run. Proper oil pressure and temperature

shall be maintained in the engine, transmission, transfer unit, and controlled differential during the

break-in run. The differential oil filter element shall be removed, cleaned, and reinstalled

following completion of the break-in run.

4.5.3.3 Simulated break-in run. A simulated break-in run (see table IV) may be

accomplished on the Army Skid Type Dynamometer in lieu of the run specified in 4.5.3. The final

ten miles of the total break-in run shall be on smooth, level, hard-surfaced roads, except that the

vehicle shall be subjected to undulating terrain by being operated over the section of road

19

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business