MIL-DTL-62013E(AT)

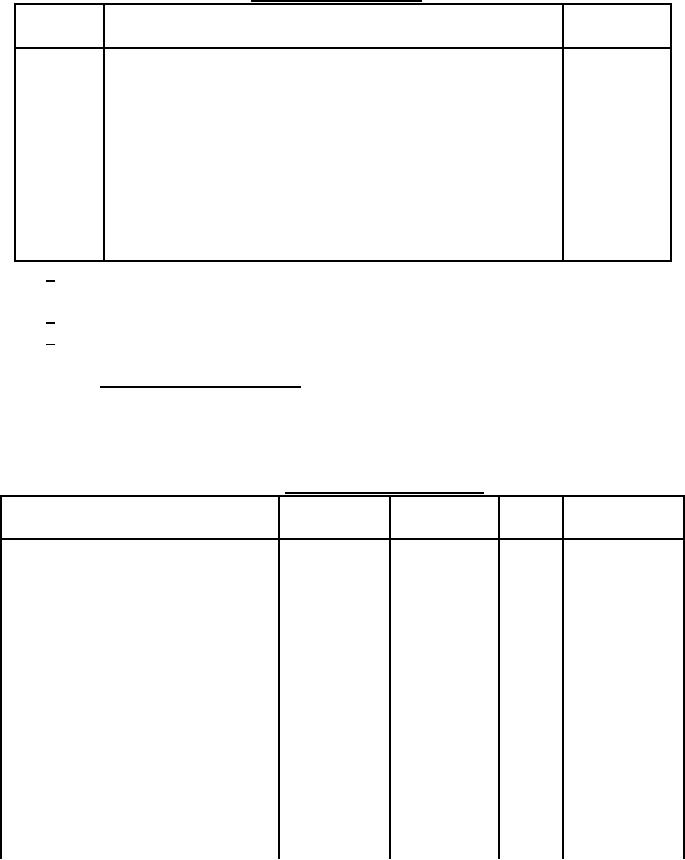

TABLE I. Classification of defects - Continued.

Method of

Category

Defect

examination

216

Paint applications, color, protective anti-skid coatings;

Visual

improper (see 3.6).

217

Decals, marking data and instruction plates; missing,

Visual

improper location or size, defective (see 3.7 and 3.8).

Visual

218

Fire extinguisher system control; data card incomplete,

improper assembly, installation, coding or protection

(see 3.10).

219

Lubrication and lubricant; improper application, materials

Visual

and coverage improper (see 3.11).

220

Workmanship; faulty (see 3.12).

Visual

1/ Fuel leaks constitutes a special defect and will result in total inspection of the lot

for this defect (see 6.5.2).

2/ Filament failures are not to be classified as major or minor defects.

3/ SIE = Standard Inspection Equipment.

4.2.2 Initial production inspection. Unless otherwise specified (see 6.2), first article

initial production inspection shall be performed on two vehicles. This inspection shall include the

examinations of 4.4 (see table I) and the tests of 4.5.4 through 4.5.36 (see table II).

Subsequently, both vehicles shall be tested for 5000 miles as specified in 4.5.4.

TABLE II. Classification of inspections.

First

Conformance

Title

Requirement

Inspection

article

tests

Bearing seals

3.3.1

4.5.5

X

X

Special kits tests

3.3.2

4.5.6

X

Winterization kit (M730A1)

3.3.2.1

4.5.6.1

X

Cab personnel heater kit (primary)

3.3.2.2

4.5.6.2

X

(M548A1)

Cab personnel heater kit

3.3.2.3

4.5.6.3

X

(secondary) (M548A1)

Cargo area personnel heater kit

3.3.2.4

4.5.6.4

X

(primary) (M548A1)

Cargo area personnel heater

3.3.2.5

4.5.6.5

X

(secondary) (M548A1)

Engine coolant heater kit

3.3.2.6

4.5.6.6

X

(M548A1)

Air brake kit (M548A1)

3.3.2.7

4.5.6.7

X

Material handling kit (M548A1)

3.3.2.8

4.5.6.8

X

16

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business